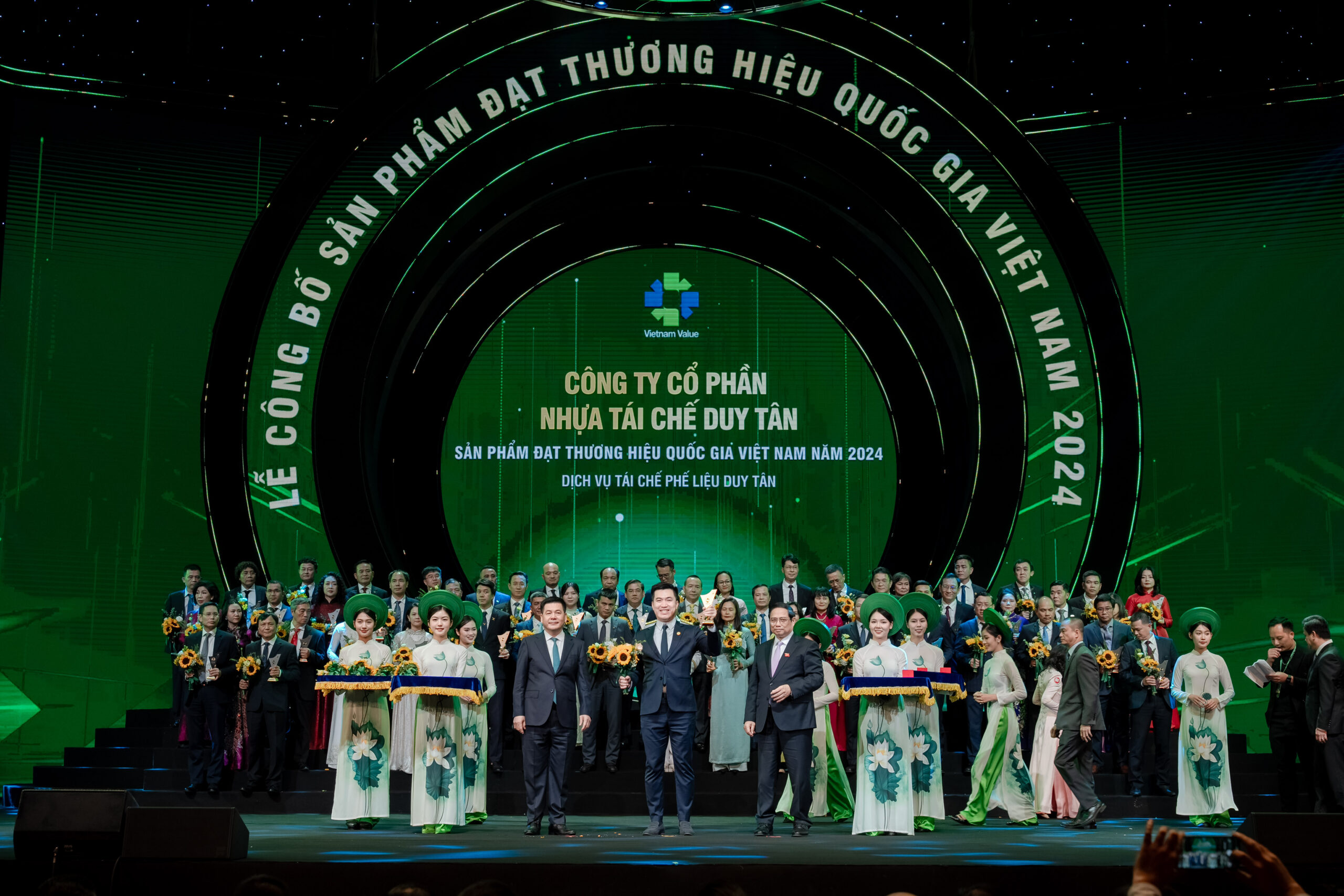

April 22, 2025 – DUYTAN Recycling (DTR) and Unilever Vietnam (UVN) held a ceremony to summarize two years of collaboration and announce their cooperation goals for 2025, marking a significant step forward in promoting a circular economy for the recycled plastics industry in Vietnam. The event was attended by representatives from domestic and international organizations, partners, and government agencies.

Under the framework of a 5-year Memorandum of Understanding (MOU), both parties are committed to taking joint action to reduce environmental pollution through the collection and recycling of plastic waste, aiming to collect and recycle 30,000 tons of plastic waste, making a positive contribution to Vietnam’s sustainable development strategy.

After two years of implementation, the Plastic Collection & Recycling project has achieved significant milestones. To date, more than 15,000 tons of plastic waste have been sorted, collected, and recycled. In addition, the project has encouraged and supported 1,100 workers directly involved in collecting, sorting, and recycling plastic waste at over 20 collection sites, providing them with protective gear (such as uniforms, helmets, gloves) and personal and household hygiene products to improve working conditions and enhance their quality of life.

Alongside recycling efforts, the project also emphasizes community education and awareness programs. Several meaningful initiatives have been implemented, including Ho Chi Minh City’s Green Living Festival 2023–2024 and the Plastic Sorting Festival in District 7, helping raise public awareness about sorting plastic waste at the source and environmental protection responsibilities.

This year’s training program emphasizes the importance of sorting plastic waste at the source to optimize the recycling process and minimize negative environmental impacts. The collaboration between Unilever Vietnam and DUYTAN Recycling not only contributes to addressing environmental pollution but also promotes the development of a circular economy, creates jobs, and raises community awareness about the significance of plastic waste sorting and recycling.

This year’s training program emphasizes the importance of sorting plastic waste at the source to optimize the recycling process and minimize negative environmental impacts. The collaboration between Unilever Vietnam and DUYTAN Recycling not only contributes to addressing environmental pollution but also promotes the development of a circular economy, creates jobs, and raises community awareness about the significance of plastic waste sorting and recycling.