On November 4 in Hanoi, the Vietnam Trade Promotion Agency under the Ministry of Industry and Trade held the Vietnam Value 2024. The event was attended by Prime Minister Pham Minh Chinh along with other members of the Party Central Committee, leaders from ministries, central agencies, and international representatives in Vietnam.

With a long-term vision, the program aims to help enterprises comprehensively evaluate and develop while promoting core values: Quality – Innovation – Pioneering Capacity. Beyond a prestigious award, the National Brand title stands as a certification of sustainable development, guiding businesses towards international standards.

The theme for 2024 – “Moving into the Green Era” – conveys a message of combining economic growth with environmental preservation, emphasizing the importance of sustainable development, especially in the context of global challenges such as climate change and resource scarcity. This year’s honorees are recognized as pioneers not only in economic growth but also in efforts to promote a green and sustainable future.

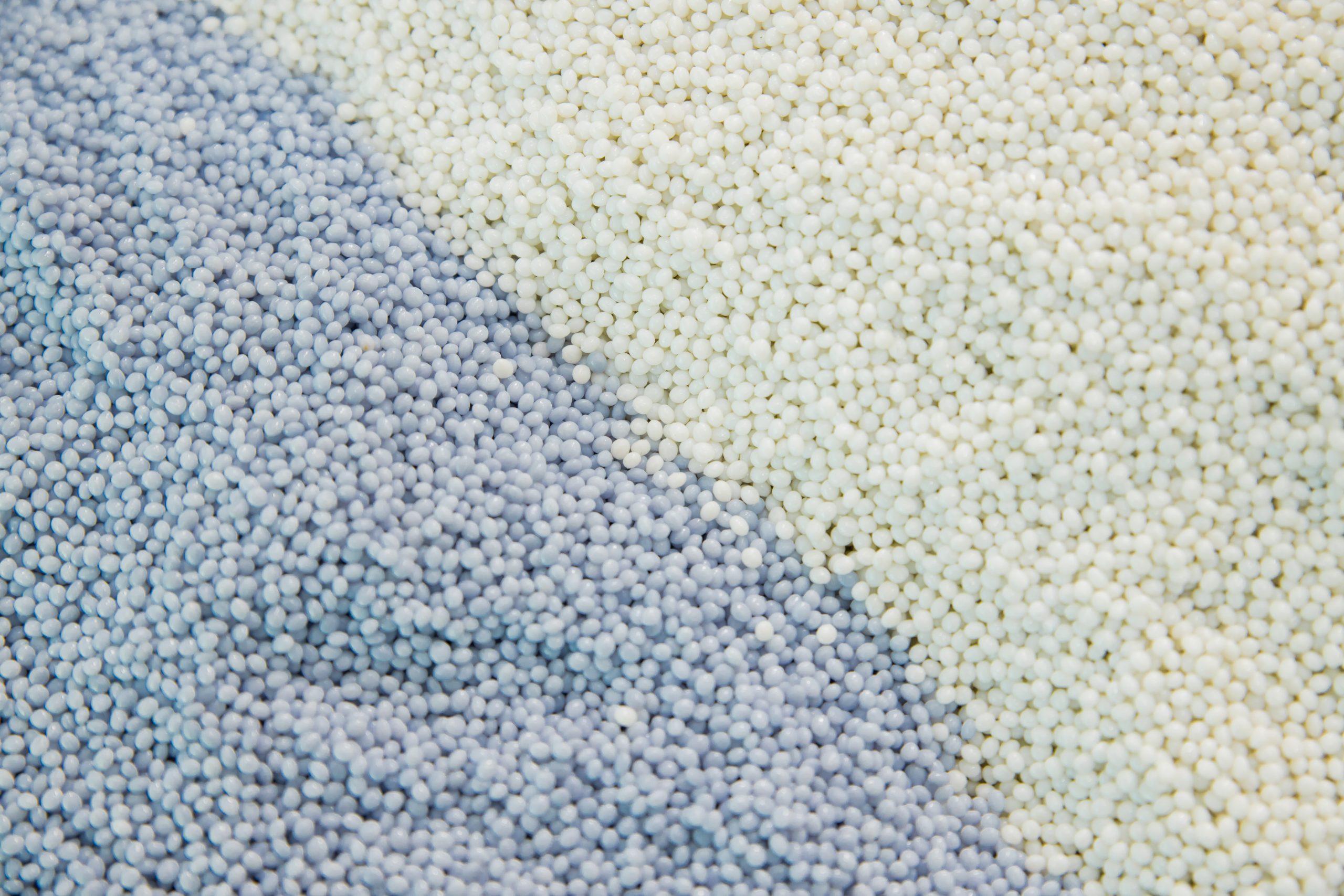

As a leading company in high tech plastic recycling in Vietnam, DUYTAN Recycling is on a mission to reduce environmental pollution, promote a circular economy, and raise community awareness about recycling. Over the years, DUYTAN Recycling has achieved remarkable accomplishments, with a current plant capacity of 60,000 tons per year, equivalent to over 4 billion plastic bottles recycled annually. Once Phase 3 is completed, DUYTAN Recycling’s designed capacity will reach an impressive 100,000 tons per year, equivalent to around 7 billion plastic bottles being collected and recycled. DUYTAN Recycling’s recycled plastic granules meet domestic demand and are exported to over 15 countries, proudly showcasing a Vietnamese enterprise capable of supplying high-quality recycled plastic to the international market.

Today, recycled plastic bottles with eco-friendly packaging are easily found in the market. While recycled plastic bottles are common in developed economies, DUYTAN Recycling’s “green bottle” carries significant meaning, as it is made from locally collected plastic waste, helping reduce pollution and promoting efficient resource use.

Being recognized as a Vietnam Value 2024 is a testament to DUYTAN Recycling’s efforts and achievements in high-tech plastic recycling in Vietnam. With a broad vision and a spirit of continuous innovation, DUYTAN Recycling is committed to investing in research and development projects, constantly advancing technology to provide customers with creative, efficient, and eco-friendly solutions. On this journey of sustainable development, DUYTAN Recycling is not only creating value for the community and environment but also contributing to a brighter future for the next generations.

The prestigious Asia Pacific Enterprise Awards (APEA) is a Regional Award Recognition programme recognising entrepreneurial excellence. APEA aims to band leading entrepreneurs and organisations across Asia to spur greater innovation, fair practices and growth in entrepreneurship, creating a successful entrepreneurial ecosystem which will then shape Asia to sustainable economic and social growth.APEA honours business leaders and organisations who have shown outstanding performance and tenacity in developing successful businesses, whilst not neglecting the social responsibilities that come with leadership.

Enterprise Asia believes in providing a platform, due recognition and publicity to Asia’s leading entrepreneurs and organisations to promote sustainable leadership, innovation and responsible entrepreneurship. Building on the success and strength of the programmes across 36 countries and markets, Enterprise Asia will continue to expand its reach in the following countries to create a holistic platform for fellow alumni to build connections, share ideas and play a part in building an Asia that is rich in entrepreneurship.

The city of Quy Nhon, in partnership with the United Nations Development Programme (UNDP), officially launched the Waste Sorting at Source Program and inaugurated the Material Recovery Facility (MRF) today. The events mark a significant step forward in promoting circular economy models, enhancing plastic waste management, and reducing ocean plastic pollution.

Quy Nhon City has made significant efforts in advancing its waste management. With a daily waste generation of approximately 580 tons, the city has actively sought innovative solutions to tackle plastic waste. The Waste Sorting at Source Program, piloted in the wards of Ngô Mây and Nguyễn Văn Cừ, involves 8,000 households and engages 200 informal waste workers. By July 2025, the program will be expanded citywide.

Mr. Nguyen Duc Toan, Vice Chairman of the Quy Nhon City People’s Committee, emphasized the city’s ongoing efforts to maintain its recognition as a clean city. He stated, “Quy Nhon is proud to have been awarded the ASEAN Clean Tourist City Award for 2020 and again for 2024-2026. Through the Waste Sorting at Source Program, we are committed to preserving this recognition and ensuring that our city remains a benchmark of environmental sustainability. By piloting this program in two wards and expanding it citywide by 2025, we aim to significantly improve our waste management practices, contributing to a cleaner environment and the city’s long-term development.”

Ms. Mette Møglestue, Deputy Head of Mission, Norwegian Embassy in Hanoi, emphasized the importance of innovation and source sorting, stating, “Waste sorting at source is crucial for waste management in general and recycling in particular. It is the foundation for any systematic intervention along the waste value chain. Innovation is essential for smarter, better, and more effective waste management.” She further emphasized Norway’s ongoing support for Vietnam’s circular economy and waste management efforts, particularly in regions like Quy Nhon.

As part of the event, Quy Nhon City also hosted the Inauguration of the Material Recovery Facility (MRF) at the Long My Waste Treatment Complex. Operated by Binh Dinh Environment JSC, the MRF represents a circular business model accelerating plastic waste management. Supported by UNDP and local government, the Facility will receive recyclable materials collected through the Waste Sorting at Source Program, further segregated them before sending to recyclers.

Ms. Ramla Khalidi, UNDP Resident Representative in Viet Nam, expressed her enthusiasm for the advancement, stating, “Today’s launch of the Waste Sorting at Source Program, the inauguration of the Material Recovery Facility (MRF), and our Innovation Day on Plastic Reduction mark significant milestones in our collective journey towards sustainable waste management and a more sustainable future for Quy Nhon City and Binh Dinh province.” She highlighted the vital role that partnerships play in ensuring the long-term success of these initiatives.

During the inauguration, Mr. Tran Van Tam, Deputy Director of Duy Tan Recycling JSC, spoke about their partnership: “The launching of the MRF represents our collective effort to reduce waste, promote recycling, optimize resources for a circular economy. Duy Tan Recycling will work closely with the MRF to close the loop of plastic lifecycle, turning plastic waste into recycled materials that will re-enter the production chain.”

The HCMC Union of Business Association (HUBA) and the Sai Gon Giai Phong (SGGP) Newspaper on the evening of August 29 held a ceremony to award the title ‘HCMC Green Business 2024’ to 98 enterprises.

Speaking at the award ceremony, Chairman of the HCMC Union of Business Association (HUBA) cum head of the organization board of the HCMC Green Business 2024 title, Nguyen Ngoc Hoa said that among 98 selected companies for the title ‘HCMC Green Business 2024’, 53 are manufacturers and 45 are working in the trade – service – real estate sector.

These outstanding enterprises have demonstrated a strong commitment to strictly complying with environmental standards, using resources efficiently, and developing green initiatives. It is not only businesses’ efforts but also affirms the importance of sustainable development in the business strategies of HCMC’s business community and entrepreneurs, contributing to the economic and social development of the country.

The Chairman of the HUBA congratulated selected companies awarded the Green Business title this year. He believed the recognition would be a driving force for the city’s business community to continuously pioneer in the progress on sustainable development, and building a greener, cleaner, and more livable city.

DUYTAN Recycling is extremely proud to be honored as a Green Enterprise in 2024! This is the second consecutive year DUYTAN Recycling has received this prestigious award, affirming its tireless efforts in sustainable development and environmental protection.

Addressing the event, Vice Chairman of HCMC People’s Committee, Vo Van Hoan hoped that the “HCMC Green Business” awards would be a passport for businesses to enter international markets.

He requested the SGGP Newspaper and the HUBA continue to enhance the quality of the award based on the ESG (Environmental, Social, and Governance) criteria with the goal of developing the title into a national brand recognized by the international community.

He emphasized that green growth and the development of green businesses are the right directions; otherwise, enterprises will not survive or have opportunities to enter the global market. Vietnam has negotiated and signed many free trade agreements, presenting numerous opportunities to enter foreign markets but there are also many difficulties and challenges. Major markets are very interested in green growth, renewable energy use, and low labor intensity. They set ESG (Environmental, Social, and Governance) criteria that domestic and international businesses must adhere to the regulations. The government will have mechanisms and policies to support businesses during this process.

According to the Vice Chairman of the Municipal People’s Committee, HCMC has identified three main pillars of green growth, including the legal framework, measurement criteria, and green models. In terms of the legal framework, the city has built around 80 programs, projects, strategies, and policies to support all production sectors. Green models including green localities (Can Gio District), green production facilities, green schools, and green buildings must be valuable products.

The southern metropolis is ready to listen to businesses to provide them better support.

——

DUYTAN Recycling HONORED IN THE TOP 50 TYPICAL SUSTAINABLE DEVELOPMENT ENTERPRISES 2024 – WASTE REDUCTION PIONEER AND CIRCULAR ECONOMY

DUYTAN Recycling Company and Ajinomoto Vietnam have recently signed a cooperation agreement to collect and recycle plastic packaging as part of the Extended Producer Responsibility (EPR) programme.

HCM CITY — DUYTAN Recycling Company and Ajinomoto Vietnam have signed a cooperation agreement to collect and recycle plastic packaging as part of the Extended Producer Responsibility (EPR) programme.

This initiative aims to enhance packaging collection and recycling, reduce plastic waste in the environment and foster a circular economy in waste management.

Aligned with Ajinomoto Group’s sustainable development goals, Ajinomoto Vietnam has undertaken several initiatives, including reducing greenhouse gas emissions, minimising food loss, decreasing plastic pollution and bolstering efforts in packaging collection and recycling throughout its product lifecycle.

Under the new partnership, DUYTAN Recycling and Ajinomoto Vietnam plan to collect and recycle 94 tonnes of plastic waste in 2024, equivalent to approximately 7.3 million plastic bottles. This collaboration not only highlights their commitment to advancing waste sorting, collection and recycling but also extends to communication campaigns aimed at promoting environmental protection and making a positive community impact.

Plastic waste poses significant challenges due to its difficulty in decomposition and its substantial burden on global waste management systems. Recognising this, DUYTAN Recycling is dedicated to advancing a circular economy in Việt Nam as a core component of its long-term strategy, employing cutting-edge technologies and modern processes to support a greener, more sustainable environment.

In Việt Nam, the EPR policy is crucial for developing a circular economy. It allows businesses to meet rising partner expectations and engage more deeply in the global value chain. DUYTAN Recycling is proud to be listed among the approved recycling units by the Ministry of Natural Resources and Environment, as announced in Notice No 86/TB-BTNMT on February 20, 2024.

For manufacturers, recycling has become a legal requirement. According to the Law on Environmental Protection 2020 and Decree 08/2022/ND-CP, starting January 1, 2024, manufacturers and importers of batteries, accumulators, lubricants, tires, and packaging (including plastics and paper) are mandated to recycle their products and packaging after they are discarded by consumers.

DUYTAN Recycling started construction in June 2019 on a 65,000sq.m site within Đức Hòa Hạ Plastic Industrial Park in the southern province of Long An, with a production capacity of 100,000 tonnes per year. The facility features a state-of-the-art production line recently imported from Europe. In addition to adhering to ISO management system standards, the company’s products meet the stringent requirements of the US Food and Drug Administration (FDA) and hold international certification from the European Food Safety Authority (EFSA).

This certification underscores the quality of its recycled plastic pellets, which are suitable for manufacturing food-contact products, including drinking water bottles. The factory uses ‘ Bottle-to-Bottle’ recycling technology, transforming used plastic bottles into new plastic pellets and thereby creating a continuous loop of plastic bottle production, which helps reduce reliance on fossil fuels.

Ajinomoto Vietnam Company, established in 1991, is a wholly foreign-invested entity under the Ajinomoto Group. The company operates two representative offices in HCM City and Hà Nội, as well as manufacturing plants in Biên Hòa (since 1991) and Long Thành (since 2008). Additionally, Ajinomoto Vietnam operates three large distribution centers and 66 branches across 63 provinces and cities, supported by 298 sales teams and employing nearly 2,300 staff members. The company’s core philosophy is to ‘Contribute to bringing health and happiness to the people and society of Việt Nam through providing quality products and valuable initiatives’

Via Viet Nam News – The National English Language Daily

From January 1, 2024, Extended Producer Responsibility (EPR) regulations mandate producers and importers of lubricants, batteries, accumulators and types and various packaging types to either recycle or pay fees to bolster waste recycling efforts. Việt Nam News reporters spoke to leaders from DUYTAN Recycling to explore the effects and opportunities stemming from this new mandate on their respective businesses and soeicty at large.

Sustainable solutions for waste management in Việt Nam

Extended Producer Responsibility (EPR) holds businesses responsible for handling and recycling waste arising from the production process. Expected outcomes of this policy include increased recycling rates and the establishment of a circular economy model in Việt Nam.

However, to successfully implement EPR policy in Việt Nam requires joint efforts from the Government, businesses and the community. There is a need to streamline regulations and raise awareness about the benefits of eco-friendly products and environmental protection for both present and future generations. Through these efforts, we can contribute to promoting the circular economy, working towards environmental protection and sustainable development.

DUYTAN Recycling has been prepared for EPR for a considerable period of time. The company is greatly honoured to be listed among the top 24 units capable of recycling packaging products, as announced by the Ministry of Natural Resources and Environment on February 20, 2024, in Notice 86/TB-BTNMT. This signifies the company’s compliance with the recycling standards set by the ministry.

The main factor in successful waste recycling is investing in high technology that meets international standards. With synchronous and professional investment, DUYTAN Recycling always commits to product quality that meets international requirements and has full certifications such as EFSA, FDA. In 2023, we were honoured to receive the High-Tech Enterprise Certificate licensed by the Ministry of Science and Technology. We always operate for the goal of constantly investing in improving our recycling capacity, ensuring output and quality, meeting the demand for recycled plastic for domestic and foreign businesses.

To enhance the management, recycling and reduction of plastic waste that pollutes the environment and oceans, we have invested and built a factory providing high quality recycled plastic products with “Bottle-to-Bottle” technology. Each used plastic bottle will be recycled into plastic pellets, creating a new cycle, thereby helping to reduce the use of fossil fuels.

We believe that the promotion of a circular economy in Việt Nam is a crucial objective in the company’s long-term development strategy. As a result, we have actively engaged in forums and seminars on the circular economy with the aim of sharing the company’s experiences and social initiatives with both domestic and international audiences. Through these sessions, DUYTAN Recycling aims to inspire and encourage more companies to join hands in the future to contribute to the establishment of a sustainable circular economy.

Via Viet Nam News – The National English Language Daily

Along with partners DUYTAN Recycling, the global brand Samsonite and House of Luggage are calling for trade-ins of any brand or size and offering up to 50 percent off from April 1, 2024 to April 31. May 2024.

Customers can bring any brand suitcase to the Samsonite store system, or locations that sell Samsonite or House of Luggage brands to exchange for a new suitcase at a discount of 30% – 50%.

For Online customers, after ordering directly from hol.com.vn and receiving a new suitcase, the customer will bring the old suitcase to the system’s nearest store location for recycling.

The recovered old suitcases will be collected and processed by DUYTAN Recycling (DTR), Asia Environment Company (MTAC) and VINTRANS transportation unit, which are accompanying the program.

MTAC will separate the components of the suitcase (outer plastic shell, inner fabric layer, aluminum frame pull handle, wheels). The group of recyclable plastics will be transferred to DTR to be recycled into plastic resins, then produced into new useful products to give to schools and the community.