Việt Nam News reporters spoke to companies’ leaders to explore the effects and opportunities stemming from this new mandate on their respective businesses and society at large.

From January 1, 2024, Extended Producer Responsibility (EPR) regulations mandate producers and importers of lubricants, batteries, accumulators and types and various packaging types to either recycle or pay fees to bolster waste recycling efforts. Việt Nam News reporters spoke to leaders from DUYTAN Recycling to explore the effects and opportunities stemming from this new mandate on their respective businesses and soeicty at large.

Sustainable solutions for waste management in Việt Nam

Extended Producer Responsibility (EPR) holds businesses responsible for handling and recycling waste arising from the production process. Expected outcomes of this policy include increased recycling rates and the establishment of a circular economy model in Việt Nam.

However, to successfully implement EPR policy in Việt Nam requires joint efforts from the Government, businesses and the community. There is a need to streamline regulations and raise awareness about the benefits of eco-friendly products and environmental protection for both present and future generations. Through these efforts, we can contribute to promoting the circular economy, working towards environmental protection and sustainable development.

DUYTAN Recycling has been prepared for EPR for a considerable period of time. The company is greatly honoured to be listed among the top 24 units capable of recycling packaging products, as announced by the Ministry of Natural Resources and Environment on February 20, 2024, in Notice 86/TB-BTNMT. This signifies the company’s compliance with the recycling standards set by the ministry.

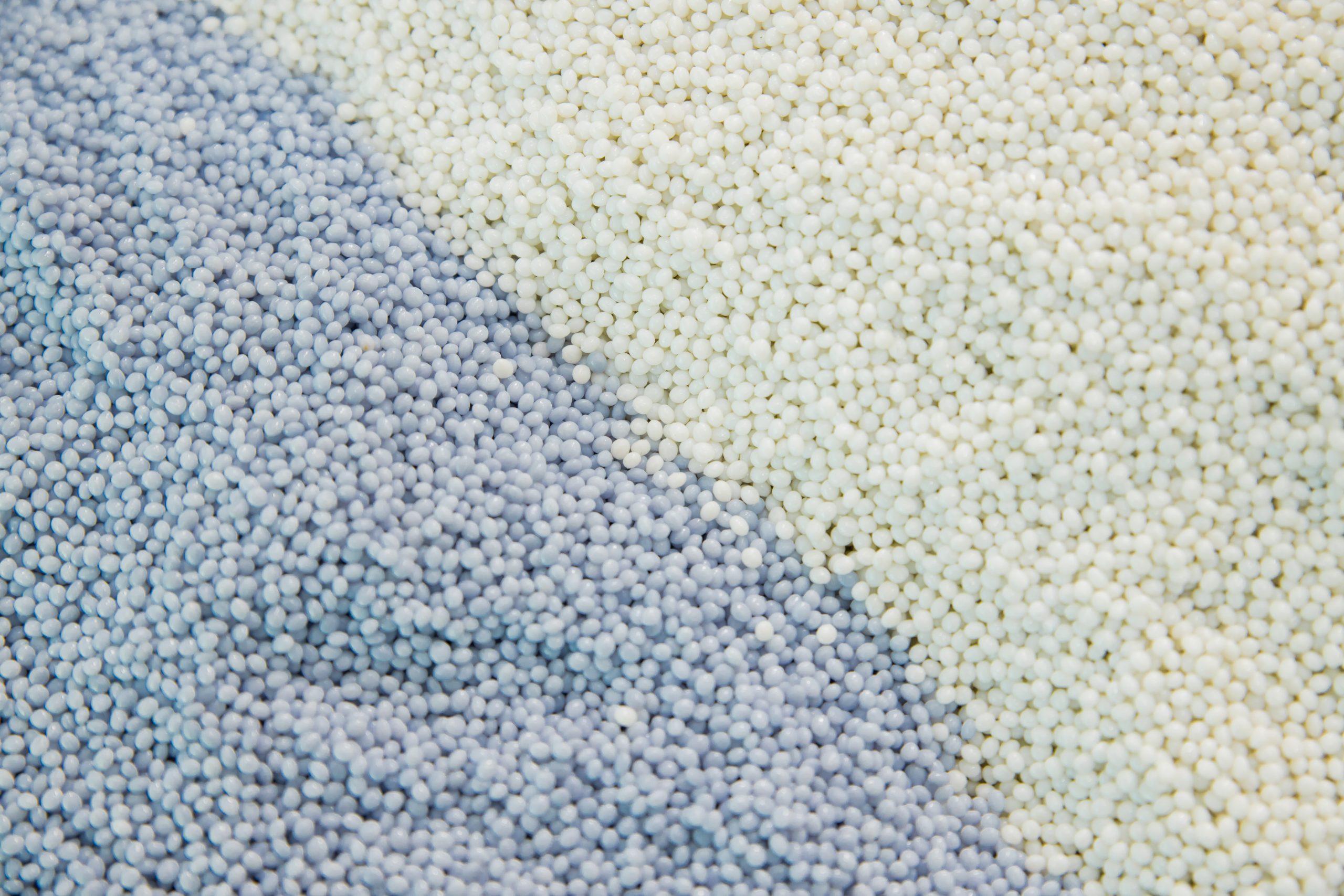

The main factor in successful waste recycling is investing in high technology that meets international standards. With synchronous and professional investment, DUYTAN Recycling always commits to product quality that meets international requirements and has full certifications such as EFSA, FDA. In 2023, we were honoured to receive the High-Tech Enterprise Certificate licensed by the Ministry of Science and Technology. We always operate for the goal of constantly investing in improving our recycling capacity, ensuring output and quality, meeting the demand for recycled plastic for domestic and foreign businesses.

To enhance the management, recycling and reduction of plastic waste that pollutes the environment and oceans, we have invested and built a factory providing high quality recycled plastic products with “Bottle-to-Bottle” technology. Each used plastic bottle will be recycled into plastic pellets, creating a new cycle, thereby helping to reduce the use of fossil fuels.

We believe that the promotion of a circular economy in Việt Nam is a crucial objective in the company’s long-term development strategy. As a result, we have actively engaged in forums and seminars on the circular economy with the aim of sharing the company’s experiences and social initiatives with both domestic and international audiences. Through these sessions, DUYTAN Recycling aims to inspire and encourage more companies to join hands in the future to contribute to the establishment of a sustainable circular economy.

Via Viet Nam News – The National English Language Daily